25 mesh brass mesh rolled can hold its shape well.

Brass Wire Mesh Decorative Projects

Four different sizes of brass wire mesh are required by our client: 65 mesh, 40 mesh, 25 mesh and 8 mesh. These brass meshes will be cut into pieces, bent and fixed to stainless steel structure, maintaining bending shape to create a modern model, with gradient effects.

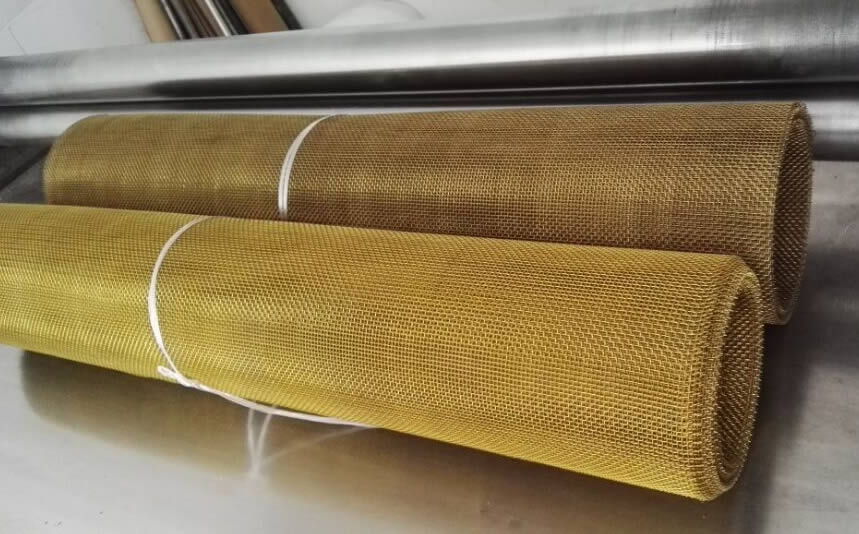

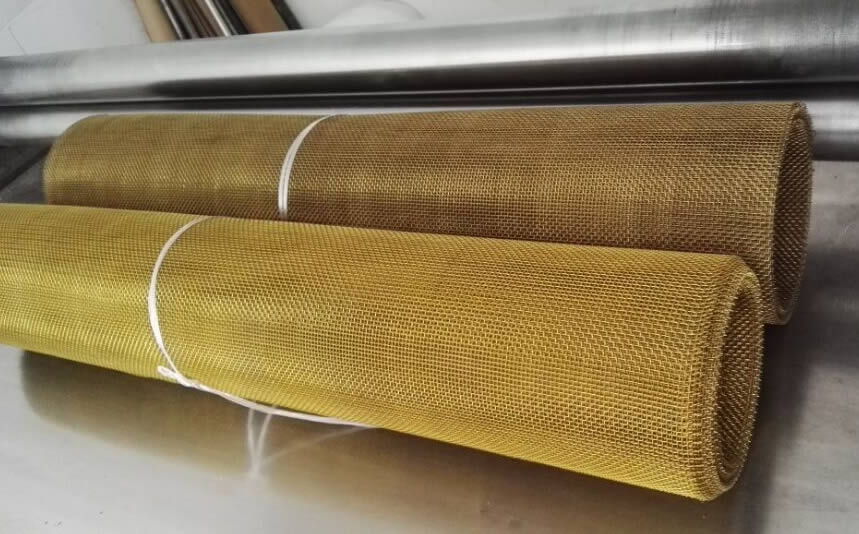

Brass mesh picture:

25 mesh brass mesh rolled can hold its shape well.

Brass wire mesh roll with 0.9 m width and 30 m length, packed using paper core and paper & plastic film.

Problem:

Brass mesh, with bright shinny surface, is a good choice to be used as decorative models. But, the more denser brass mesh will be more soft, that is the reason why it is also called brass cloth. As for the 65 mesh, it is so flexible that it can not hold its shape.

Available solutions:

Result:

Considering the appearance of this model, solution 1 is recommended and finally acceptable by our client.